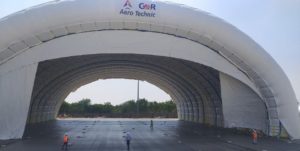

An inflatable Hangar, first of its kind in India, was commissioned at GMR Aero Technik’s MRO facility at Rajiv Gandhi International Airport .The Hangar H-45 is suitable to store two narrow body aircraft such as one A320 NEO and one B737-900.

The hangar has been manufactured by Buildair Inflatable Structural Solution of Spain. Buildair hangars come in five sizes – H-20 measuring 20 mts, H-35 measuring 35 mts, H-45 measuring 45 mts, H-54 measuring 54 mts and the largest H-75 measuring 75 mts.

The hangar has been manufactured by Buildair Inflatable Structural Solution of Spain. Buildair hangars come in five sizes – H-20 measuring 20 mts, H-35 measuring 35 mts, H-45 measuring 45 mts, H-54 measuring 54 mts and the largest H-75 measuring 75 mts.

Some of the Buildair inflated hangars in service since 2013 are located around the globe at Getafe, Lérida and Leon in Spain, Budapest in Hungary, Jeddah, Red Sea project, Amaala and Neon in Saudi Arabia, Leznica and Sidwin in Poland, Santiago in Chile, and Singapore. The hangars range from 75 mtrs to 15 mtrs in size.

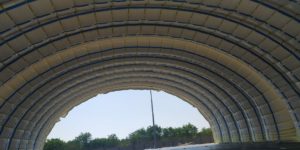

The inflatable hangar is formed by low pressure tubes (around 20 mbar), aligned parallel to each other forming a “rib-cage” structure. Structural stability of the inflatable structure is guaranteed both lengthwise by the support of the lateral air tubes, and crosswise through the internal pressure in the tubes. The hangar is designed with considering wind velocity and direction of the airport / place it will be installed. The body of the structure is electrically transparent to navigation aids such as ILS, DME, VOR frequencies.

The fabric of the tubes is a technical low-weight high-tensity textile with a wide range of customization to the users specification, including colour, camouflage, UV and infrared protection, temperature resistance or even infrared camouflage. Apart from the standard sizes offered by Buildair, the hangars can be designed ad-hoc, based on customer’s specific requirement. The Membrane is of woven polyester base cloth with PVC coating. they are fire-retardant (classified: M2 NFP 92 507) and with temperature stability between –30ºC and +70ºC. The technology is developed in collaboration with the University of Polytechnic of Catalonia through extensive research.

The fabric of the tubes is a technical low-weight high-tensity textile with a wide range of customization to the users specification, including colour, camouflage, UV and infrared protection, temperature resistance or even infrared camouflage. Apart from the standard sizes offered by Buildair, the hangars can be designed ad-hoc, based on customer’s specific requirement. The Membrane is of woven polyester base cloth with PVC coating. they are fire-retardant (classified: M2 NFP 92 507) and with temperature stability between –30ºC and +70ºC. The technology is developed in collaboration with the University of Polytechnic of Catalonia through extensive research.

The hangars come with external waterproof layer isolation. It avoids water leaks in the hangar as well as air or dust infiltrations coming from outside, because it covers the hangar from ground to ground and it is sealed to the ground on both sides.

The portable hangars including design, manufacture and testing takes between 1 months to 6 months depending on the size and for setting up of the hangar at customer’s location will take between 2 days to 18 days depending on the size and 15-30 minutes of inflation time. No foundation is required for these hangars and they can be moored with high resistance straps, specifically designed to properly distribute existing loads.

The portable hangars including design, manufacture and testing takes between 1 months to 6 months depending on the size and for setting up of the hangar at customer’s location will take between 2 days to 18 days depending on the size and 15-30 minutes of inflation time. No foundation is required for these hangars and they can be moored with high resistance straps, specifically designed to properly distribute existing loads.

The hangar is equipped with lighting, exhausts, air conditioning (optional), fire system, etc. The hangars have real time tracking of all parameters which can be monitored through any computer or smart phones. The low maintenance inflatable hangar comes with 3 years guarantee, periodical inspections, training and recurring training.